All products are independently selected by our editors. If you buy something, we may earn an affiliate commission. Learn More >

Many factors come into play when it comes to making the perfect espresso, but one crucial component that can’t be overlooked is temperature consistency. This is where a PID controller comes into play. This advanced technology optimizes the brewing process, enabling coffee brewers to create delicious espresso shots consistently.

As espresso enthusiasts continually seek ways to perfect their brewing technique, the implementation of PID controllers in espresso machines has become increasingly popular. By employing such a system, coffee connoisseurs can truly unlock the potential held within the beans, resulting in a more remarkable espresso experience.

✔ Quick Answer

The Role of Temperature in Espresso Extraction

Picture this: You’re about to pull that glorious espresso shot, and the water temperature is too low. The result? A weak, under-extracted espresso that tastes sour.

On the other hand, if the water is too hot, your espresso will turn out bitter and over-extracted. Achieving that sweet spot of temperature is crucial to unlocking those delightful flavors hidden in the coffee grounds. This is where the PID device can really help you nail the perfect shot time and time again.

Introducing the PID Controller

Alright, let’s cut to the chase: PID stands for Proportional Integral Derivative, but don’t let the technical jargon intimidate you.

In essence, a PID controller is just a nifty gadget installed in modern espresso machines that helps to maintain a stable and precise temperature during the brewing process.

It’s like a trusty clever thermostat for your coffee machine, ensuring that the water temperature remains constant, like a conductor guiding an orchestra to harmony.

Benefits Of Using PID Espresso Controllers

Home espresso coffee machines equipped with PID controllers can achieve a high level of temperature and pressure stability. These controllers constantly monitor and adjust the water temperature and pressure to ensure that they remain within the desired range.

This level of precise control allows baristas and home users alike to achieve consistent brewing results every time they pull a shot.

Furthermore, PID controllers offer a more energy-efficient solution compared to traditional thermostats found in many older espresso machine steam boilers. By precisely regulating the heat and steam pressure, there is less chance of excessive energy consumption or unnecessary wear on the machine’s components.

Lastly, the presence of a PID temperature controller allows for greater customization of the entire espresso brewing process.

Users can adjust the boiler temperature and pressure within specific limits to cater to various coffee beans, roast profiles, and personal preferences.

Understanding Espresso PID Controllers

The PID controller works by continuously calculating the difference between the set temperature and the actual temperature, known as the error. It adjusts the heating elements according to this error, making gradual changes to achieve the desired temperature.

The controller is composed of three distinct elements:

Proportional: This part of the controller responds to the present error and adjusts the machine according to the current discrepancy in temperature.

Integral: This element works on a cumulative basis, removing any lingering residual error. This ensures that even minor discrepancies are accounted for, leading to a more stable temperature throughout the brewing process.

Derivative: The derivative part of the PID controller is designed to predict the future rate of change in temperature. It provides a damping effect, preventing overshooting of the set temperature.

PID controllers offer many advantages compared to traditional home and commercial coffee machines, such as enhanced consistency and accuracy. By implementing a PID controller, baristas can have more control over the process, minimizing factors that may affect espresso quality, such as fluctuations in water temperature.

Precision in temperature control is vital for extracting the best flavors and maintaining consistency across multiple espresso shots.

In terms of setting up a PID controller, it is essential to find the correct tuning parameters. These parameters, referred to as Kp, Ki, and Kd, represent the proportional, integral, and derivative gains, respectively.

Also, it’s worth noting that it is not a one-fits-all type of device and each PID controlled coffee machine and environment may require different tuning values, but once you dial in the PID to the optimal settings, you will greatly improve the performance of the espresso machine.

Types Of PID Controllers

PID controllers come in various forms, depending on the type of espresso machine you have. Below I have listed a few of the common types you will most likely come across.

Single Boiler PID Systems

This type of PID controller is found in single boiler espresso machines. It governs both brewing and steam boiler temperatures. While it’s a significant upgrade from non-PID machines, it does have some limitations.

Dual Boiler PID Systems

For the coffee aficionados who love multitasking, dual boiler PID systems are the answer. These machines have separate boilers for brewing and steaming, allowing you to pull shots and froth milk simultaneously without compromising on temperature stability.

Heat Exchanger PID Systems

Heat exchanger espresso machines utilize a single boiler but have a heat exchanger to separate brewing water from the steam. With a PID temperature adjuster, these machines offer improved temperature control and really help with maintaining a consistent water temperature.

How Does A PID Controller Works In An Espresso Machine?

The main function of a PID controller is to maintain the desired water temperature within a tight range.

It does so by continuously measuring the actual temperature and comparing it to the set point. Upon detecting any deviation, the controller adjusts the heating element accordingly.

Proportional control is the first component of the PID controller. It modulates the power of the heating element proportionally to the temperature difference between the set point and the measured value. A larger deviation results in a greater power output, while a smaller difference leads to a decreased output.

Integral control is the second component and aims to eliminate any residual error that may persist over time. It adjusts the power output based on the accumulated error, ensuring optimal temperature control. By continuously compensating for the error, it minimizes any fluctuations.

Derivative control is the final component of the PID controller. It anticipates any future temperature changes by analyzing the rate of change in the error.

This foresight helps in quickly counteracting any potential temperature spikes or drops, maintaining the desired temperature with accuracy.

The interplay of these three components allows the PID controller to provide precise temperature control, which is crucial for consistent espresso quality. With a well-tuned PID controller, an espresso machine can deliver stable temperatures, minimizing unwanted fluctuations and resulting in a reliable and enjoyable espresso experience.

Fine-Tuning Your PID Settings

Once you’ve embraced the PID revolution, it’s time to fine-tune those settings. Remember, every coffee bean is unique, and playing around with PID parameters can bring out entirely different flavor profiles.

Understanding Temperature Profiles

Different beans and roast levels have distinct preferences when it comes to extraction temperature.

Experiment with your PID settings to find the temperature range that complements the specific characteristics of your coffee.

Common PID controller espresso Temperature and Infusion stages:

| Profile | Description |

| Ramp Soak | This profile starts at a low temperature and gradually ramps up to a higher temperature, then holds steady at that temperature for a set period of time before cooling down. This profile is often used for lighter roasts or for delicate coffees that require a slower, gentler approach. |

| Preinfusion | This profile includes a short period of low pressure and low temperature before the machine ramps up to full pressure and temperature. This allows for a more even extraction and can help prevent channeling. |

| Saturated | In a saturated profile, the temperature is held steady at a high temperature throughout the entire extraction. This can be useful for darker roasts or for coffees that require a more aggressive approach to extract all of the flavors. |

| Declining | This profile starts at a high temperature and gradually declines throughout the extraction. This can be useful for coffees with a lot of acidity that need to be balanced out, or for coffees that have a lot of sweetness that can be emphasized by a lower temperature. |

| Stepped | A stepped profile includes several temperature changes throughout the extraction, with each step lasting for a set period of time. This can be useful for coffees with complex flavor profiles that require different temperatures to bring out different notes. |

Adjusting PID Settings for Different Coffee Beans

As a coffee lover, you might enjoy trying out various beans from different regions. With a PID controller, you can easily adapt to these changes by adjusting the temperature settings to match each bean’s preferences.

Adapting to Ambient Conditions

Environmental factors, such as humidity and room temperature, can impact your PID controller’s performance. Be prepared to make slight adjustments to compensate for these changes and maintain a stable brewing temperature.

Setting Up A PID Controller

The following paragraphs outline how to set up a PID controller in an espresso machine.

First, gather the necessary tools and equipment, such as a PID controller, a compatible espresso machine, and some basic tools like a screwdriver or a wrench. Make sure to choose a compatible PID controller for your espresso machine model, as they can vary depending on the make and manufacturer.

Once you have the appropriate PID controller, switch off and unplug your espresso machine to ensure safety during installation.

Then, open the housing of the machine to access its internal components. Locate the temperature probe, which is typically connected to the boiler or the group head. This probe will be replaced or supplemented by the PID controller. Carefully disconnect the probe and keep it aside.

Next, connect the PID controller components according to the manufacturer’s instructions. There are typically three main connections: the temperature sensor, the power supply, and the relay output.

First, attach the temperature sensor to the previously identified location in the boiler or group head.

Then, connect the power supply to an appropriate source within the espresso machine. Finally, connect the relay output to control the heating element in the boiler or group head.

Once all connections are made, ensure they are secure and safe to prevent electrical issues or malfunctioning. Close the housing of the espresso machine, taking care not to pinch or damage any wires during the process.

Reconnect the espresso machine’s power source and turn it on.

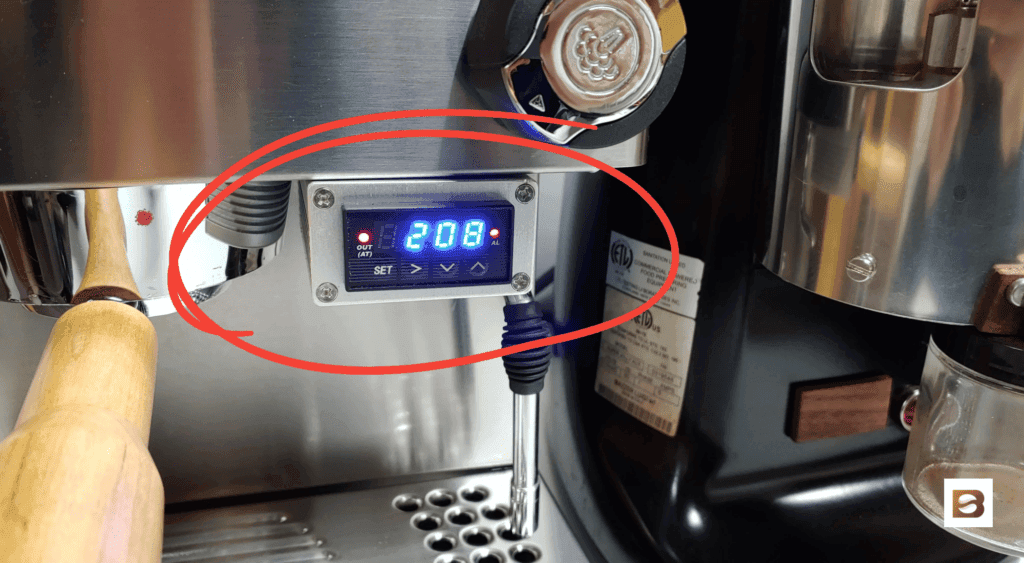

At this point, the PID controller’s user interface or display should become accessible. Program the desired temperature settings by following the manufacturer’s instructions.

Make sure to set the appropriate values and use a thermometer to verify the accuracy of the PID-controlled temperature. This step is crucial to guarantee consistent results.

Common Problems With PID Controllers

PID controllers found in some of the best espresso machines have gained popularity due to their ability to create precise and consistent temperatures. However, they can come across several issues that can be frustrating for users.

One common issue with PID controllers is the overshooting of the set temperature. This happens when the temperature increases beyond the desired value before dropping back down and stabilizing.

This phenomenon is typically caused by a poorly-tuned PID controller.

Tuning the controller involves adjusting the controller’s Proportional, Integral, and Derivative parameters to fine-tune the heating and cooling processes. Manufacturers may include tuning instructions or auto-tuning functions to help users overcome this issue.

Another significant problem some users experience is the lack of responsiveness from the PID controller. This might occur due to a mismatch between the controller and the espresso machine’s heating and cooling capacities.

In this case, the controller may struggle to achieve the desired temperature quickly, resulting in poor temperature control.

Users should ensure that their PID controller is compatible with their espresso machine’s power specifications.

Additionally, component failure or incorrect wiring can cause issues with PID controllers. Users may experience erratic behavior, inconsistent temperature control, or even failure to heat altogether. It is essential to inspect the espresso machine’s components and internal wiring regularly, replacing any faulty parts or cables when necessary.

Lastly, although PID controllers are designed to provide precise temperature control, they can still be affected by external factors. Variations in ambient temperature, equipment age, and machine placement can impact performance.

While PID controllers are a valuable addition to an espresso machine, it is crucial to recognize potential issues and troubleshoot them effectively to ensure a consistent and enjoyable coffee-making experience.

Maintaining An Espresso Machine PID Controller

A PID controller in an espresso machine plays a vital role in ensuring the water temperature is consistent and stable. This in turn assures that the coffee extraction process is smooth and of high quality.

To keep this component functioning optimally, regular maintenance is necessary.

Firstly, it is essential to verify the temperature readings of the PID controller. To do this, simply utilize a separate thermometer to measure the water temperature and compare it with the values displayed on the controller. If there is a significant difference, adjustments or calibration may be required.

Cleaning the espresso machine is also crucial in maintaining the PID controller. Dust and dirt can accumulate and compromise the performance of the temperature sensors.

Regular cleaning of the machine and its components, including the PID controller, will help maintain accuracy and prevent issues from arising.

Additionally, it is important to monitor your espresso machine for any signs of wear and tear, particularly within the electronics and wiring of the PID controller. Potential problems may be indicated by fluctuating temperature readings, irregular functions, or unresponsive buttons.

Addressing these issues promptly can prevent damage to the PID controller and ensure that it continues working correctly.

Conclusion

Congratulations! You’ve now journeyed into the world of PID controllers and how they can transform your espresso experience. As a seasoned coffee expert, I can confidently say that investing in a PID-controlled espresso machine is a game-changer.

The stability, consistency, and flavor-enhancing powers of PID controllers will undoubtedly take your espresso-making skills to new heights.

So, whether you’re an aspiring home barista or a coffee shop owner, consider making the leap and embracing the PID revolution. Explore the different types of PID controllers and find one that suits your automatic espresso machine needs.

Remember, fine-tuning the PID settings for different coffee beans and conditions is part of the fun – it’s like discovering new flavor profiles with each adjustment.

And don’t forget, while PID control brings innovation, the charm of manual brewing will never fade. Balance the best of both worlds, combining your barista skills with technology to create the ultimate coffee experience for you and your customers.

You Might Also Like